About the client – a snap shot

Chennai-based Mudhra Fine Blanc Pvt. Ltd., is an automotive component manufacturer specialising in fine blanking and stamping. It is part of MIM a joint venture between Mudhra and two Italian companies IMA and Malvestiti, both leaders in the space. A technology leader in fine blanking, Mudhra supplies sheet metal forming parts and has over 20 years of experience in India’s leading auto-component hub. It manufacturers fine blanked latches and pawl that are critical components in automobile door and window assembly. Mudhra is a trusted partner for all leading auto-brands in the country.

Client’s challenge and the business need

At Mudhra, several high volume parts which undergo 100% inspection for visual defects or surface defect detection, was done manually. This process had many challenges,

- To ensure quality, 200% inspection was being performed, one in-process and the other at the end-of-the-line, thereby consuming additional manpower and time.

- With the Quality Inspection process operating only for a limited number of hours in a day, backlog was common that impacted throughput. Due to this, bottlenecks in production were observed too.

- Attrition was high, having to provide re-training to the new recruits, which was loss of cost and time, besides incurring of additional expenses for frequently hiring people for Quality Inspection.

- Quality of output was low with defects not getting always identified, due to the fatigue factor that set it among the Quality Inspectors. This was resulting in needless expenditures in the downstream processes for the bad parts.

- Human judgement errors and biases were commonplace impacting output quality.

- The risks and the costs associated with customer complaint was high.

Client wanted a solution to automate the inspection process that could bring in inspection accuracies at speed leading to increase in throughput volume and quality. After exploring and evaluating several conventional solutions, Client chose to partner Jidoka Technologies as their solution offered the required guarantees with regards to inspection accuracies that no other player in the space could provide.

Jidoka Technologies – Kompass Solution was successfully implemented on Tigris hardware platform

Jidoka Tech’s team of Engineers had several discovery sessions with the Client to understand the requirement for the solution. Tigris was deployed for 100% Quality Inspection, which was thorough and did not have to rely on the biases of human workforce.

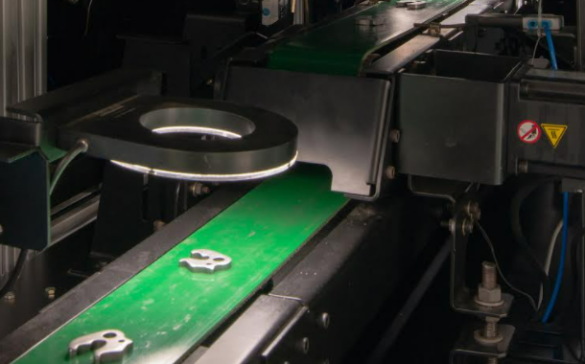

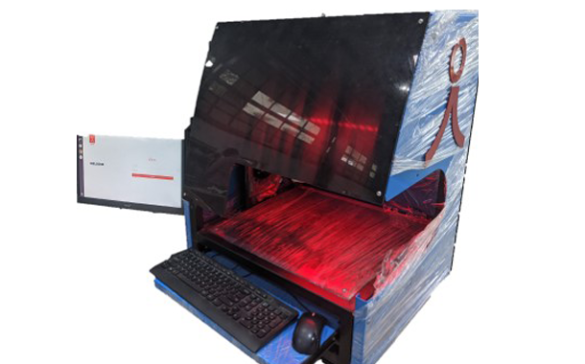

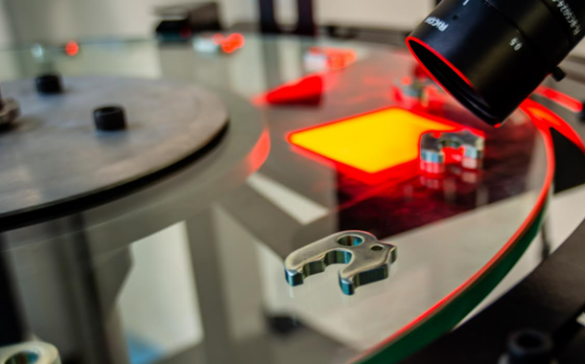

- Tigris – a trademarked product architecture consisting of the right number of cameras, light and PC was leveraged to capture the digital twin of the product, which was flat and light weight.

- The software platform, where real-time decision making was mapped with the state-of- the-art AI, to create an end-to-end system for visual defect detection, where upto 120 decisions per minute were delivered.

- Once the installation was done, a data science engineer from JidokaTech was deployed on site to work with the Client to refine the system further.

- The desired results were delivered with the AI-enabled automation process with 100% inspection done by the machine accompanied with several business benefits.

- As the modular architecture was scalable, any increase or decrease in demand in production was met with.

Business Benefits

- Significant cost savings was observed due to the AI-based Quality Control and with the end-of-the-line Quality Inspection getting eliminated.

- Dependency on manpower was reduced and re-training costs saved that was used for skilling Quality Inspectors constantly.

- Automation led to 24X7 Quality inspection that resulted in 33% increase in throughput.

- Italian parent company is now considering to adopt Jidoka Tech Solutions for their other units.

- Mudhra is exploring other areas and business units to leverage and apply Jidoka Tech solution.

- A significant improvement in Customer experience was observed with increase in throughput and defect detection accuracy leading to better customer satisfaction.

- Decrease in excess rejection and resultant wastefulness.

[quote font=”tahoma” font_size=”13″ font_style=”italic” color=”#262626″ bgcolor=”#f9f9f9″]Vikram Prabhakar, COO, Mudhra Fine Blanc Pvt. Ltd., said, “Our engagement with Jidoka Tech team has been rewarding since the beginning of our partnership. Before signing up, we had several questions that Jidoka Tech answered with absolute clarity that led us to partner them for our QC requirements.” He added, “We realised that translating human intelligence into an algorithm was not easy and had to be clear about our defect definitions. Today with the support from Jidoka Team we are getting better at it everyday and are confident of completely replacing human inspection with automation for this part family, soon.”[/quote]

About Jidoka Technologies

Chennai-based Jidoka Technologies is a next generation start-up founded in 2018, by technology leaders, Sekar Udayamurthy, Dr. Krishna Iyengar and Vinodh Venkatesan. It delivers cutting-edge engineering solutions to automate the process of visual quality checks at high speed by leveraging Deep Learning, AI/ML and Analytics. Jidoka’s state-of-the-art automated cognitive QC solution enhances the quality and efficiency of QC in the manufacturing process. It harnesses and mirrors human reasoning in defect detection delivering 98% or higher accuracy in the QC process and a significant increase in throughput.

Jidoka Tech works with manufacturers across automotive, pharma, general manufacturing, electronics, textiles and printing industrial domains currently and will expand to other verticals, in future. The organisation aims to expand its services across global markets of UK, Europe and Australia besides serving across the Indian sub-continent, North America and South East Asia, by 2025.

Please visit, https://jidoka-tech.com, for more information.